Your Guide to Fire Rated Wall Protection

We often get architects, facility managers and builders ask – “Is your wall protection fire rated for use in Group 1 buildings.” The answer to this question is ‘Yes, it is Group 1 fire rated to Australian standards, using the ISO9705 testing method.’ Although this might suffice for most, it is important to have an understanding of what Group 1 certification actually means and the test methods used to arrive at it. Read on to learn what this actually means and what to look out for.

How is the Group Number determined?

There are two different test methods acceptable to determine a group number for a wall lining. The Cone Calorimeter test and the Full-Scale Room Test (ISO9705).

The Cone Calorimeter test has traditionally been used as it is more simple and cost-effective, although it does have its limitations. This method uses a small-scale sample (100 x 100mm) of the test material and an oxygen calorimeter. This method measures the heat and smoke release rates.

The Full-Scale Room Test is as per the AS ISO 9705-2003 Standard and is the most accurate predictor of how a wall-lining will perform in the case of a fire. This uses a room (3000mm L x 3000mm W x 3000mm H) that has the walls and ceilings lined with the material getting tested, with a heat flux meter inside. The room is set alight from the corner and the data is measured when the heat flux meter records 1 MW (when flashover occurs). Although regarded as more accurate, this method is significantly more expensive to perform.

Is either test acceptable?

No. Historically the cone calorimeter test was the primary means for determining Group Number, however is generally only regarded as suitable for materials such as gypsum plasterboard, timber linings and rigid non-thermoplastic foams. Being a small scale test, it only tests the material composition itself, independent of other factors that may come into play in a real-life situation, including the exact orientation and location of the material, proximity to the fire source and the thickness and texture of the material.

Materials that are not regarded as acceptable include…

- Materials with profiled surfaces where more than 50% of the surface is rebated more than 10mm from the highest point

- Materials containing joints, large holes, cracks, or fissures

- Materials that melt or shrink away from a flame

- Materials that intumesce, swell, bend or collapse appreciably when exposed to radiant heat

- Materials with a reflective surface

- Linings in which surface coatings or layers are capable of delaminating from the substrate.

In regards to rigid vinyl wall protection, the ISO 9705 Full-Scale Room Test is regarded as the only acceptable testing method, given that the material is susceptible to melt or shrink away from the flame and could potentially delaminate from the substrate in the event of a fire.

The safety and compliance of our products is our number one priority at Acculine. Our Palladium Rigid Vinyl wall protection products have been tested in accordance with ISO 9705 to provide you and your stakeholders the peace of mind to use in your buildings.

Please contact [email protected] to a copy of our Group 1 fire certificate, for the relevant wall protection product.

What is a Group Rating, what does it actually test and what buildings do they apply to?

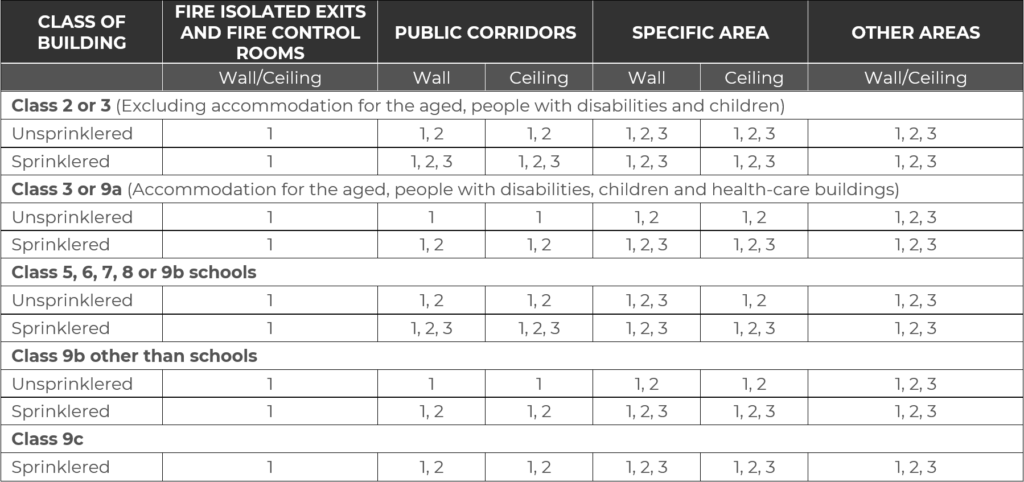

Group numbers is a value from 1 to 4 that is determined by a test. Group 1 materials perform the best and Group 4 materials perform the worst in a fire. Buildings are classified into categories from Class 2 to Class 9, based on their application. Below is a table of each category and which Group number is required in each, including Aged Cares, hospitals, schools and general accommodation such as hotels. If you have any questions about a specific building and the group rating required, please dont hesitate to reach out to us at [email protected] and our team will gladly assist.

The National Construction Code (NCC) is the statutory document that stipulates the performance requirements for materials to be regarded as ‘fire-rated wall linings’ and based on these requirements, where they can be used. Below is a summary derived from the Australian Building Codes Board’s information which explains the nitty gritty of the performance requirements, how they are tested and its limitations, in plain English.

Although there are a total of 13 performance requirements for Fire Resistance within Section C of the NCC, the relevant performance requirement for Fire-Rated Wall Linings is CP4 ‘Safe conditions for evacuation’. This states that in the event of a fire “…a material and an assembly must, to the degree necessary, resist the spread of fire and limit the generation of smoke and heat, and any toxic gases likely to be produced…” This is to make it possible to escape in the case of a fire within the building.

In order to quantify the performance requirement to be met for wall linings, C1.10(a)(ii) is regarded as a Deemed-to-Satisfy (DTS) Provision, and achieves this in part by requiring wall and ceiling linings to meet the fire hazard properties of Specification C1.10. Clause 4(a) of the Specification requires…

a) for non-sprinkler protected buildings: a smoke growth rate index not more than 100 or an average specific extinction area less than 250 m2/kg; and

b) for all buildings: a group number, the specific value of which varies with building classification, location, and if the building is sprinkler protected.

References

1. Standards Australia, Determination of fire hazard properties Wall and ceiling linings, 2015

2. Standards Australia, Method of test for heat and smoke release rates for materials and products using an oxygen consumption calorimeter, 1998 (R2016)

3. International Organization for Standardization Reaction-to-fire tests — Heat release, smoke production and mass loss rate — Part 1: Heat release rate (cone calorimeter method) and smoke production rate (dynamic measurement)

4. Standards Australia, Fire tests – Full-scale room test for surface products, 2003 (R216)